Tacmina Q Series pumps are at the core of modern flow chemistry trends including decentralized, modular pharma micro factories. These innovations enable low volume production of common pharmaceuticals as well as same-day development of bespoke treatments and are transforming pharmaceutical supply chains.

With microreactors integrating entire synthetic sequences on milliliter-scale chips, milliliter and microliter control of critical fluids coupled with pulseless, no shear flow and a fully purgeable dead volume are critical when automating the micro production of fluid-based materials for rapid deployment.

Using the typical batch equivalence, a single 1L flow reactor can replace a 100L stirred tank reactor.

Pumps commonly used in low-volume pharma production and drug R&D applications include:

- Syringe Pumps – for non-continuous, batch flow applications, where highly accurate metered flow is required, process runtime is limited by the syringe capacity

- Peristaltic Pumps – easy to clean, simply replace the flow path with a new sterile tubing kit, however peristaltic pumps may produce pulsation and inaccurate metering

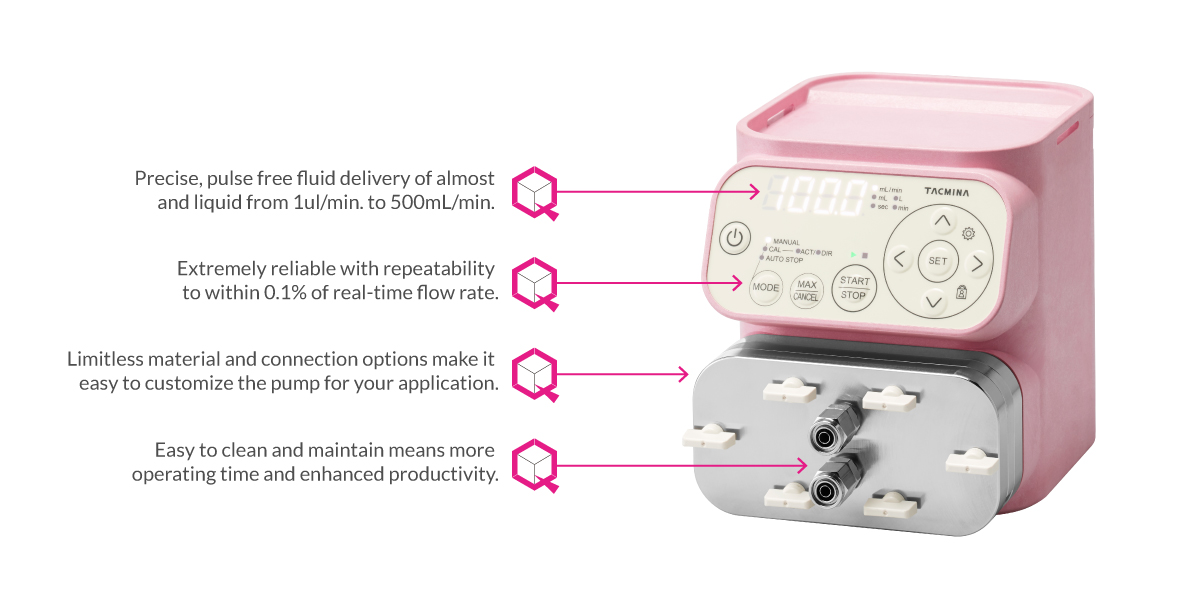

- Tacmina Q Series Diaphragm Pumps – pulseless, low-to-no shear flow with microliter accuracy and the ability to purge any dead volume make the Tacmina Q Series pump an ideal choice for flow chemistry and continuous production applications